„Climate change is the key challenge of our time. Our generation is the first to experience the rapid rise in temperature all over the world and probably the last challenge that the imminent global climate crisis will face.”.

Katowice, December 2018

VISION

THE GREEN SIDE OF SGR GROUP

SGR Biomethane S.r.l. born from a pioneering Italian start-up in 2012, operating in the field of renewable fuel and smart grid technologies, with particular reference to biogas Upgrading projects and biomethane. It was indeed one of the first Italian companies to have implemented the raw biogas upgrading process into biomethane by means of membrane technology.

Innovation and cutting-edge technology are the characteristics that have enabled the company to rapidly establish itself on the biomethane market as well as establishing strategic partnerships in order to provide high-performance, flexible and easy-to-manage solutions.

MISSION

INNOVATION AS ALLY FOR

OUR TIME CHALLENGES

Our core business and reference market is represented by public and private companies, involved in the organic waste management. Taking the opportunities offered by the most advanced technologies and the incentives promoted by policy

makers, the circular economy can be realized. We are particularly focused on:

• Companies involved in MSW management, water treatment plants and landfills.

• Industrial and Agricultural Companies managing organic and industrial waste (meat processing, food processing, animal manure, sewage sludge, wine lees etc.)

• Potentially convertible Biogas plants with

membrane upgrading technology.

AN ECO-FRIENDLY SUSTAINABLE PROCESS

The raw biogas is a natural fuel produced through anaerobic digestion: a natural biological process where, in absence of oxygen, the degradation

of organic substances occurs due to a selected microbial flora. During anaerobic digestion, the complex organic substance is decomposed into its

elemental constituents and the energy contained in the chemical bonds that compose it is transferred and stored in the methane gas that is released

during the final stages of the process. Each organic biomass with the presence of carbon, based on its fundamental elements, has both a different biogas productivity and a different degradation rate, from a few weeks to a few

months. The entire natural process has no environmental impact. So, when added to the intrinsic benefits deriving from the use of biomass itself, makes

anaerobic digestion a truly eco-sustainable process

SEVERAL ROLES, A SINGLE CONTACT

A strong financial situation combined with the high technological know-how, lets SGR Biomethane play the absolute protagonist role on the global market,

proposing flexible and tailor-made solutions for each project.

The matrix of roles which SGR Biomethane can operate with includes:

• EPC General Contractor,

• Construction Supervision,

• Design & Engineering,

• Procurement e Supply,

• Equity & Finance,

• O&M,

• Consulting.

The production of upgraded biomethane and the introduction into the grid has several advantages:

• It contributes to the replacement of fossil energy sources with renewable sources coherently with the objectives set by the Paris agreement;

• It can be used in the transport sector by contributing to the achievement of the 10% quote from biofuels set by the international climate agreements;

• It allows logistical savings thanks to the storage and capillary capacity of the national natural gas grid, allowing it to be perfectly integrated with

the non-programmable and intermittent renewable energy sources.

What only recently appeared as a futuristic scenario, today with SGR Biomethane is already present. Indeed, we have all the requirements to fully enter

the world of LNG, we use to call “BML” a neologism that strongly identifies the Liquefied Biomethane. In this regard, the commitment in the R&D is fundamental for us by means of the active participation in working groups where we cooperate with Universities, Research Laboratories and other far-sighted companies to make processes, still under phase study, ready to be applied on industrial scale. Only in this way can the supply chain be considered

complete and the circular economy path really closed, allowing alternative use and storage solutions not only for solving logistical problems, but for opening the way to the supply of huge means of transport such as trucks and ships too.

Our Technology

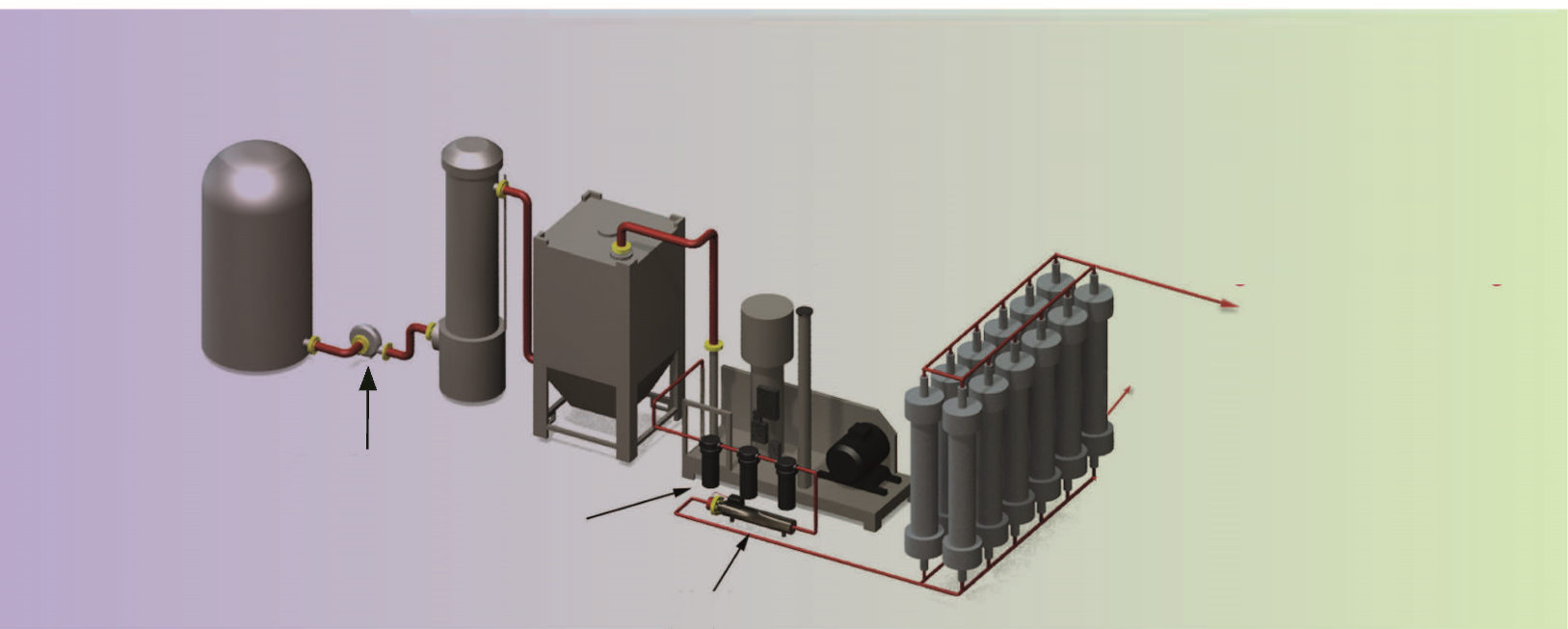

SGR Biomethane adopts cuttingedge solutions at high quality and competitive level compared to other more traditional technologies. In particular, the most widely applied technology for the raw biogas upgrading system has great potential for development. It is in fact highly flexible, versatile and modular, able to adapt to variations in flow over time. It is based on membrane modules, with the aim of reducing operating and investment costs with the contemporary chance of achieving a recovery efficiency expected up to 99.5%.

The membranes for biogas upgrading in biomethane, with specific physical selection of the contained carbon dioxide, are the consequence of a strategic

agreement with the company Air Products, the American world leader in the technical and industrial gases market. Air Products PRISM PB membranes are used to separate the precious methane from carbon dioxide. The resulting methane flow can be injected into the national grid or used as fuel for CNG vehicles,

or even LNG ones.

The membranes, by exploiting a selective permeation, separate the methane molecules from carbon dioxide and water vapour; two or three stages are necessary, each composed of several membranes collected in racks, to obtain the desired purity and recovery of methane.

Air Products has been a leading – company in the world for over 75 years. The main activity of the company in the field of industrial gases consists in the supply of atmospheric and process gases, as well as related equipment, to the production markets including refining and petrochemical products, metals, electronics and food/beverages.

Air Products is also the world’s leading supplier of liquefied

natural gas equipment and technology.

Being a passive technology that uses only the pressure of the biogas and the permeability of the membranes themselves, membranes represent a very

reliable solution as there are no moving mechanical parts and do not require start-up times.