OERTLI Induflame designs and plans individually designed industrial solutions for industrial combustion technology independently and completely.

Engineering and industrial enterprises

Delivery from one source. Both the burner and the design of the entire system and delivery to the customer. With this orientation we take care of existing and new customers.

Conversion of installations in order to apply the new emission requirements based on the amendment of the German standard BImschV and LRV. Cost savings through individual combustion technology solutions.

All types of controls and adjustments with PLCs in case of unsuccessful and unsuccessful execution, including visualization and PLS connection, guaranteeing safety at work. Modern computer technology forms a management system with complete solutions with relatively simple process technology and screen monitoring, combined with full manual intervention.

Industrial burners

Restoration of the Oertli Induflame brand with a full range of new industrial burners with a combustion capacity of 2 – 40 MW, as well as further development of the world-renowned mixing unit, which achieved NOx values below 60 mg / Nm³ NOx in the first series of experiments and which can to be offered at an unsurpassed level of price / performance thanks to the optimized design.

CIB from 1,5 to 10,5 MW

CIB – Compact industrial burner

Power range: from 1.5 to 10.5 MW

Suitable for: industrial gas oil, fuel oil, natural gas, combined

Advantages:

• low pollution combustion by LOW-NOx mixing device

• maximum economic efficiency thanks to an electronic combustion control system programmable with a laptop or software device

• The fan with electronic speed control guarantees economical energy consumption

• lowest sound emissions below 80 dB (A) through optimized airflow and integrated sound insulation

• compact two-part body that accommodates electrical and hydraulic components

• The rotating fan unit allows easy access to the burner head, mixing and ignition device

CIB – Compact industrial burner

Power range: from 1.5 to 10.5 MW

Suitable for: industrial gas oil, fuel oil, natural gas, combined

Advantages:

• low pollution combustion by LOW-NOx mixing device

• maximum economic efficiency thanks to an electronic combustion control system programmable with a laptop or software device

• The fan with electronic speed control guarantees economical energy consumption

• lowest sound emissions below 80 dB (A) through optimized airflow and integrated sound insulation

• compact two-part body that accommodates electrical and hydraulic components

• The rotating fan unit allows easy access to the burner head, mixing and ignition deviceGIB from 1.6 to 16 MW

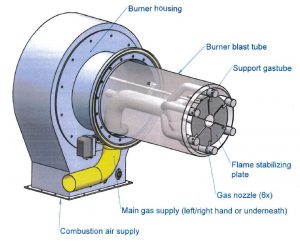

GIB – burner for gas industry with low NOx content Power range: from 1.6 to 16 MW, additional capacity on request

Suitable for: natural gas, gaseous fuels

Features:

A new series of burners that impresses with an optimal balance between price indicators, quality and economy. The optimized mixer has been tried and tested many times and can be used on almost any type of boiler. In case the lowest emission values (NOx) are required, this can be done at any time with external flue gas recirculation. The use of turbine gases and preheated combustion air up to 300 ° C depending on the performance. Additional product features are provided in response to specific inquiries.

Advantages:

• Best price-performance ratio on a modular basis

• High usability through structural engineering

• Easy to assemble – easy and fast

• Incineration with low pollution and energy efficiency

• Energy saving and environmentally friendly thanks to the highest degree of combustion

• Durable, reliable and easy to maintain

• A hot air version is possible depending on the specific application

GIB – burner for gas industry with low NOx content Power range: from 1.6 to 16 MW, additional capacity on request

Suitable for: natural gas, gaseous fuels

Features:

A new series of burners that impresses with an optimal balance between price indicators, quality and economy. The optimized mixer has been tried and tested many times and can be used on almost any type of boiler. In case the lowest emission values (NOx) are required, this can be done at any time with external flue gas recirculation. The use of turbine gases and preheated combustion air up to 300 ° C depending on the performance. Additional product features are provided in response to specific inquiries.

Advantages:

• Best price-performance ratio on a modular basis

• High usability through structural engineering

• Easy to assemble – easy and fast

• Incineration with low pollution and energy efficiency

• Energy saving and environmentally friendly thanks to the highest degree of combustion

• Durable, reliable and easy to maintain

• A hot air version is possible depending on the specific applicationDIB from 2.5 to 32 MW

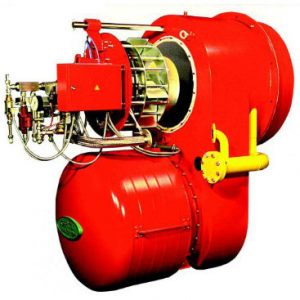

DIB – burner for the duoblock industry

Power range: from 2.5 to 32 MW

Suitable for: industrial gas oil, fuel oil, natural gas, brown coal, wood dust, special fuels, combined work with the above

Advantages:

• building on a modular principle

• maximum flame stability, through a high degree of independence from the pressure fluctuations in the combustion chamber

• mechanical or electronic capacity modulation

• High or low pressure atomization for variable control range

• Maximum reliability thanks to robust design, even in extreme conditions

• Hot air version is possible depending on the application conditions

DIB – burner for the duoblock industry

Power range: from 2.5 to 32 MW

Suitable for: industrial gas oil, fuel oil, natural gas, brown coal, wood dust, special fuels, combined work with the above

Advantages:

• building on a modular principle

• maximum flame stability, through a high degree of independence from the pressure fluctuations in the combustion chamber

• mechanical or electronic capacity modulation

• High or low pressure atomization for variable control range

• Maximum reliability thanks to robust design, even in extreme conditions

• Hot air version is possible depending on the application conditionsDSE from 7.5 to 40 MW

DSE – duoblock burner

Power range: from 7.5 to 40 MW

Suitable for: industrial gas oil, fuel oil, natural gas, special fuels, combined or simultaneous combustion of fuels

advantages:

• building on a modular principle

• extremely low polluting and energy efficient grade combustion

• energy saving and environmentally friendly thanks to the highest quality of combustion

• High or low pressure atomization for variable control range

• Hot air version is possible depending on the application

DSE – duoblock burner

Power range: from 7.5 to 40 MW

Suitable for: industrial gas oil, fuel oil, natural gas, special fuels, combined or simultaneous combustion of fuels

advantages:

• building on a modular principle

• extremely low polluting and energy efficient grade combustion

• energy saving and environmentally friendly thanks to the highest quality of combustion

• High or low pressure atomization for variable control range

• Hot air version is possible depending on the applicationMIB from 2.5 to 32 MW

MIB – monoblock burner industry

Power range: from 2.5 to 32 MW

Suitable for: industrial gas oil, fuel oil, natural gas, brown coal, wood dust, special fuels, combined work with fuels

Advantages:

• building on a modular principle

• maximum flame stability through a high degree of independence from the pressure fluctuations in the combustion chamber

• mechanical or electronic capacity modulation

• High or low pressure atomization for variable control range

• Maximum reliability thanks to robust design, even in extreme conditions

• Low airborne sound level thanks to integrated sound absorption

• Hot air version is possible depending on the application conditions

MIB – monoblock burner industry

Power range: from 2.5 to 32 MW

Suitable for: industrial gas oil, fuel oil, natural gas, brown coal, wood dust, special fuels, combined work with fuels

Advantages:

• building on a modular principle

• maximum flame stability through a high degree of independence from the pressure fluctuations in the combustion chamber

• mechanical or electronic capacity modulation

• High or low pressure atomization for variable control range

• Maximum reliability thanks to robust design, even in extreme conditions

• Low airborne sound level thanks to integrated sound absorption

• Hot air version is possible depending on the application conditionsMSE from 7.5 to 17 MW

MSE – monoblock burner

Power range: from 7.5 to 17 MW

Application for: industrial gas oil, fuel oil, natural gas, special fuels and their combination or simultaneous combustion

Advantages:

• built on a modular principle

• extremely low polluting and energy efficient combustion

• energy saving and environmentally friendly thanks to the highest quality of combustion

• High or low pressure atomization for variable control range

• Hot air version is possible depending on the application conditions

MSE – monoblock burner

Power range: from 7.5 to 17 MW

Application for: industrial gas oil, fuel oil, natural gas, special fuels and their combination or simultaneous combustion

Advantages:

• built on a modular principle

• extremely low polluting and energy efficient combustion

• energy saving and environmentally friendly thanks to the highest quality of combustion

• High or low pressure atomization for variable control range

• Hot air version is possible depending on the application conditions